Starting a clothing brand or looking to scale up your existing apparel business? One of the most important considerations is understanding the cost of manufacturing your clothing. Whether you’re a first-time entrepreneur or an experienced business owner, knowing what factors affect production costs will help you budget effectively and make informed decisions.

In this practical guide, we’ll break down the key elements that influence clothing manufacturing costs and provide a clear understanding of how to plan your budget for creating your own apparel line.

Key Factors Influencing Clothing Manufacturing Costs

When it comes to clothing manufacturing, the pricing isn’t as simple as multiplying units by a set price. Several factors come into play that can affect the total cost of production. Here are the main ones to keep in mind:

1. Material Choice

The fabric you choose is one of the biggest contributors to manufacturing costs. Premium materials like organic cotton, silk, or wool are more expensive compared to basic fabrics like polyester or cotton blends. If you opt for sustainable or high-end fabrics, your costs will naturally be higher.

2. Quantity

In manufacturing, the more units you order, the lower the cost per unit typically becomes. This is known as economies of scale. Small batch production or custom designs might be pricier because manufacturers cannot leverage the same volume discount. If you plan to produce a small number of items, expect a higher per-unit cost.

3. Design Complexity

The complexity of your design plays a major role in the cost of manufacturing. Simple, basic designs will generally cost less to produce than intricate, highly detailed pieces. For instance, a simple t-shirt may cost less to make compared to a jacket with several zippers, pockets, and unique stitching.

4. Production Location

Where you choose to manufacture your clothing impacts the cost significantly. Producing clothes locally in the USA might come with higher labor and material costs compared to overseas production in countries like China, Bangladesh, or India. However, local production can provide quicker turnaround times and potentially lower shipping costs.

5. Labor Costs

Labor plays a key role in determining the price of clothing manufacturing. Highly skilled workers, specialized labor, or ethical labor practices can drive up costs, but they also ensure quality craftsmanship. Cheap labor, often seen in lower-cost countries, can bring prices down but might result in inconsistent quality.

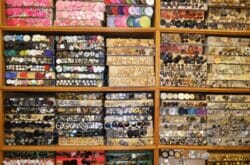

6. Finishing and Additional Details

The finishing touches, such as custom labels, embroidery, unique stitching, or added elements like buttons and zippers, add to the overall cost of manufacturing. Special treatments like washing or dyeing can also raise costs.

7. Shipping and Logistics

Shipping from the manufacturer to your warehouse or store is another cost to consider. International shipping can be expensive, depending on the shipping method, distance, and volume of goods. In some cases, importing goods from overseas might involve customs duties or taxes that can increase the total price.

8. Minimum Order Quantity (MOQ)

Many manufacturers have a Minimum Order Quantity (MOQ), which is the smallest number of units you can order per style or design. A higher MOQ might lower the per-unit cost but may not be feasible for startups or small businesses. Low MOQs, though, usually come at a higher price per item.

Difference between Wholesale and Retail Price

Wholesale and retail prices are two key factors that determine the cost of goods and services in the market. The main difference between wholesale and retail prices lies in the way they are calculated and the target customers they cater to.

Wholesale price is the cost at which products are sold in bulk to retailers or other businesses. It is typically lower than the retail price as wholesalers buys large quantities of goods directly from manufacturers or distributors at a discounted rate. Wholesale prices are set with the aim of making a profit when selling to retailers who will then sell the products to end consumers.

On the other hand, retail price is the final price at which products are sold to consumers. This price aims to offer the best price possible ensuring the business remains profitable. Retailers purchase goods from wholesalers at a wholesale price and then mark up the price to cover their operating costs and make a profit. This business plan includes marketing and advertising expenses as part of the fixed costs. Retail prices are higher than wholesale prices as they include additional costs such as rent, utilities, wages, and marketing expenses.

Wholesale prices are lower and target businesses buying in bulk, while retail prices are higher and target individual consumers purchasing goods in smaller quantities. Both wholesale and retail prices play a crucial role in the supply chain and pricing strategy of businesses.

How To Request a Price Quotation from a Garment Manufacturer

When requesting a price quotation from a garment manufacturer, it is essential to provide detailed information about your requirements to ensure an accurate estimate. Start by introducing your company and providing a brief overview of the project, including the type of garments, quantity needed, and any specific materials or designs required.

Clearly outline your expectations regarding quality standards, delivery timelines, and any additional services needed, such as labeling or packaging. Include any technical specifications or sketches to help the manufacturer understand your vision accurately.

Request a breakdown of costs, including unit price, bulk discounts, shipping fees, and any applicable taxes or duties. Inquire about payment terms, production lead times, and the manufacturer’s policies on revisions or returns.

Communicate your preferred method of contact and set a clear deadline for receiving the quotation. Be open to negotiating terms to reach a mutually beneficial agreement.

By following these steps and maintaining clear communication throughout the process, you can effectively request a price quotation from a garment manufacturer and lay the foundation for a successful partnership.

Main Factors that Affect the Cost of Manufacture Clothing

Garment costing is a crucial aspect of the fashion industry, as it directly impacts pricing, profitability, and competitiveness. Several main factors influence the overall costing of a garment:

1. Material Costs: The type and quality of fabric, trims, embellishments, and accessories used in a garment significantly affect its cost. Fluctuations in material prices due to factors like supply chain disruptions or changes in demand can impact costing.

2. Labor Costs: The cost of labor, including wages, benefits, and efficiency, plays a significant role in garment costing. Labor costs can vary based on location, skill level, and production techniques.

3. Production Volume: Economies of scale come into play when determining garment costing. Larger production volumes often lead to lower costs per unit due to efficiencies in production processes and bulk purchasing of materials.

4. Overheads: Costs related to overhead expenses such as rent, utilities, machinery, and administrative expenses also contribute to garment costing.

5. Currency Fluctuations: Exchange rate fluctuations can impact the cost of imported materials or exported garments, affecting overall costing.

6. Regulatory Compliance: Adhering to labor laws, safety standards, and environmental regulations may add to the cost of production and impact garment costing. A thorough understanding of these factors is essential for fashion businesses to accurately calculate garment costing and make informed pricing decisions.

Final Words

The cost to manufacture clothing can vary greatly depending on factors such as the type of garment, materials used, production location, and quantity produced. On average, it can cost anywhere from a few dollars to over a hundred dollars to manufacture a single piece of clothing. It is important for designers and manufacturers to carefully consider these costs and factor them into their pricing strategies to ensure profitability. Additionally, ethical and sustainable manufacturing practices may come at a higher cost, but can have a positive impact on the environment and workers’ well-being. Understanding the cost of clothing manufacture is crucial for the success of any fashion business.