Bangladesh garment production is an organized activity consisting of sequential processes such as laying, marking, cutting, stitching, checking, finishing, pressing and packaging. A complete garment has to face several processes from its order receiving to shipment. During Bangladesh garments manufacturing, a process flow chart must be needed to complete an order easily. Also, a process flow chart helps to understand a garment production method that how the raw materials are converted into wearable garments. This is a process of converting raw materials into finished products.

Garment Manufacturing steps

1. Design: Design is provided by the buyer. After placing an order buyer send the technical sheet and art-work of an order to the merchandiser. This process is done both manually or by using the computer.

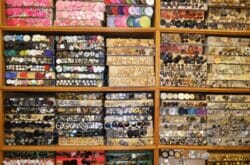

2. Receiving Fabrics: Garment factories receive fabric from overseas textile manufacturers in large bolts with cardboard or plastic centre tubes or in piles or bags. The fabric typically arrives in steel commercial shipping containers and is unloaded with a forklift. Garment factories often have a warehouse or dedicated area to store fabric between arrival and manufacturing.

2. Receiving Fabrics: Garment factories receive fabric from overseas textile manufacturers in large bolts with cardboard or plastic centre tubes or in piles or bags. The fabric typically arrives in steel commercial shipping containers and is unloaded with a forklift. Garment factories often have a warehouse or dedicated area to store fabric between arrival and manufacturing.

3. Fabric Relaxing: This step is performed by manually spot-checking each bolt of fabric using a backlit surface to identify manufacturing defects such as colour inconsistency or flaws in the material. Fabrics that fail to meet customer standards are returned to the textile manufacturer. To cut the fabric properly fabric is spread inlay form. Fabric Spreading is done manually or by using a computerized method.

4. Spreading, Form Layout, and Cutting: After the fabric has been relaxed, it is transferred to the spreading and cutting area of the garment manufacturing facility. Here, cutting parts have to sort out or make bundling to send these easily into the next process. This process is done manually.

5. Sewing: All the parts of a garment are joined here to make a complete garment. The sewing process is done manually.

6. Garments Inspection: After completing sewing, inspection should be done here to make fault free garments. Garments Inspection is done by using the manual method.

7. Garments Ironing and Finishing: Here garments are treated by steam; also required finishing should be completed here. This process is done by using the manual method.

8. Final Inspection: Finally, the complete garments are inspected here according to the buyer???s specification. Final Inspection is done by manual method.

9. Packaging and Shipping: Most Bangladesh garments are packed in plastic bags or carton box, either at the end of production or when they enter the finished goods store. Products like shirts and underwears are usually bagged and boxed directly after final inspection and enter the stores in prepacked form. For these and similar types of products, many automatic machines are used.